Integrated electronic system integration test system

With the rapid development of electronic technology, integrated electronic systems (such as avionics) have become the most critical component of weapon equipment or vehicles, and play a key role in improving the overall performance and security and reducing the cost of the whole life cycle of the system.

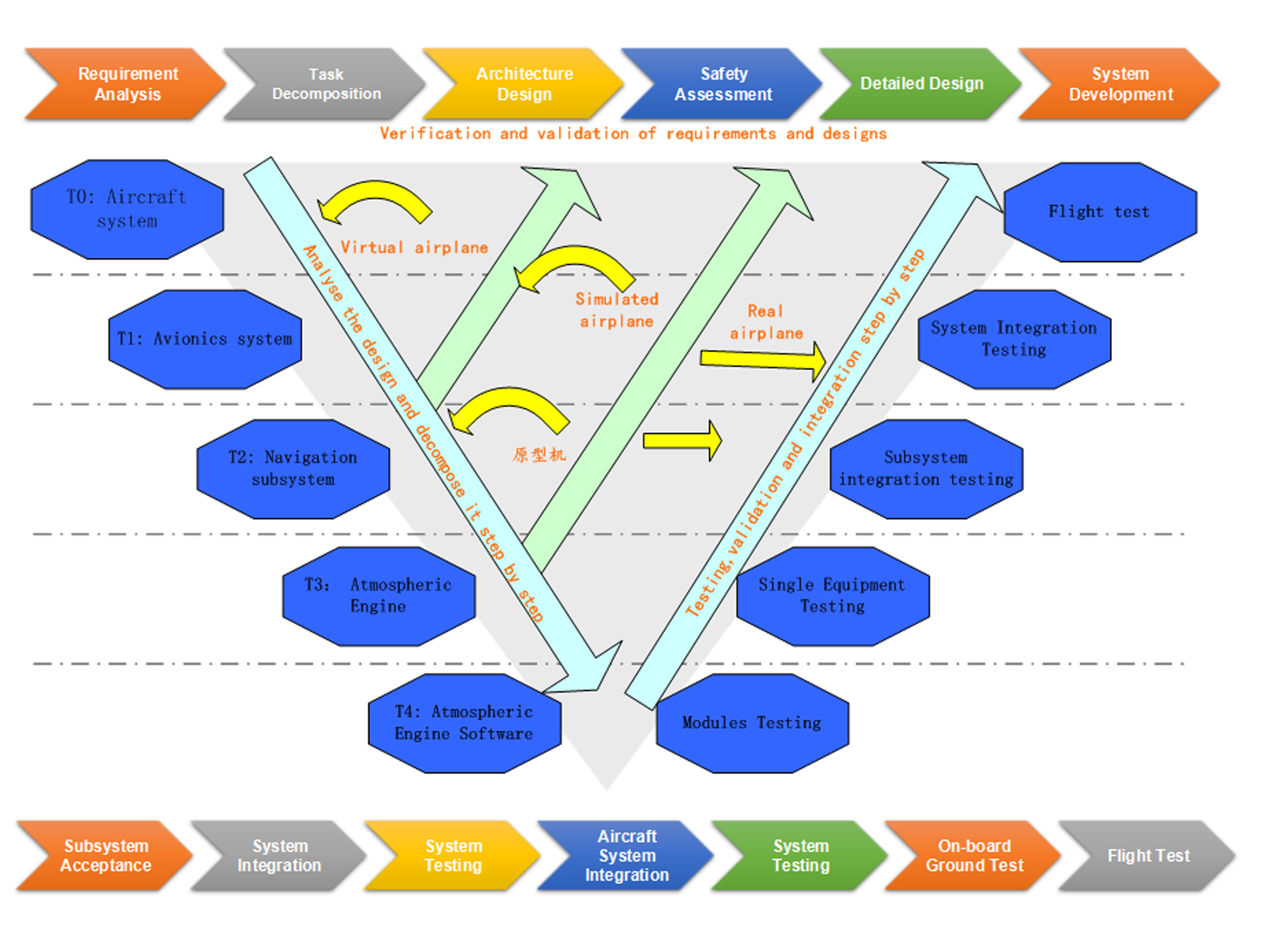

Our company adopts the "V" mode system development process and the system design idea based on this model to build a comprehensive electronic system design development and integration test platform, providing customers with a full range of tool development, platform construction, system integration and customization implementation services. The top-level design and iterative development platform for integrated electronic systems, integrated verification platform for integrated electronic systems and dynamic simulation integrated laboratory independently developed by the company have maintained leading advantages in the industry.

Principle and Method of Integrated Testing

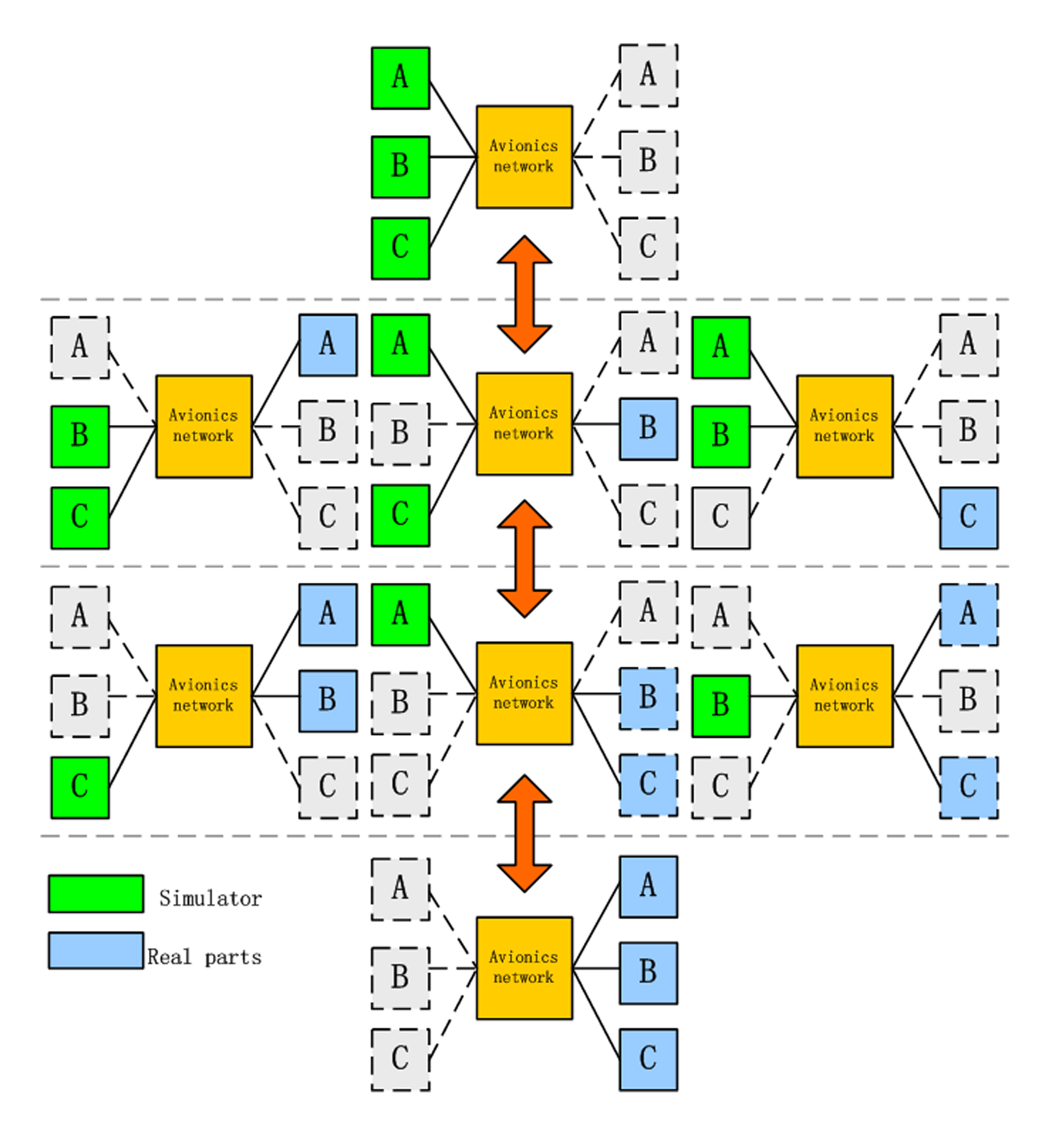

With the enlargement of the scale of integrated electronic systems, the interconnection and cooperation among systems are becoming more and more complex. In order to improve the efficiency of system integration and reduce the cost of labor and time, scientific methods must be adopted to reduce the complexity of experiments.The scientific and efficient method of system integration is to transform the mathematical simulation model into a real simulation model (simulation) with physical interface, and gradually complete the integration of the whole electronic system by replacing the real one with the simulation one by one. This method is conducive to finding and locating problems in time in the process of integration.

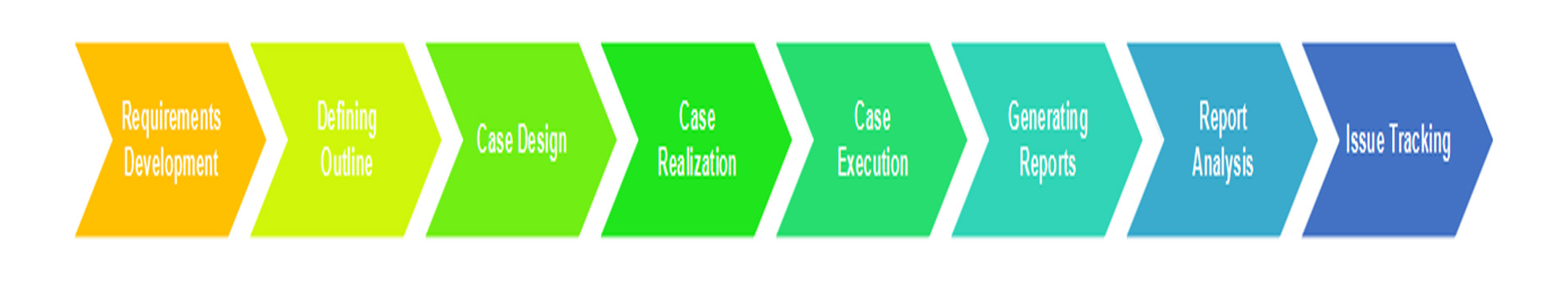

Generally, the test of integrated electronic system adopts two ways: excitation-response test and dynamic comprehensive test. With the help of automated testing technology, the testing process can be solidified in the form of test cases, and coordinated with test results to achieve tracking and regression of test problems.

For complex integrated electronic systems, the whole testing process needs to be managed orderly, including test flow management, test configuration management, test case management, test problem management and test data management.

Solution:

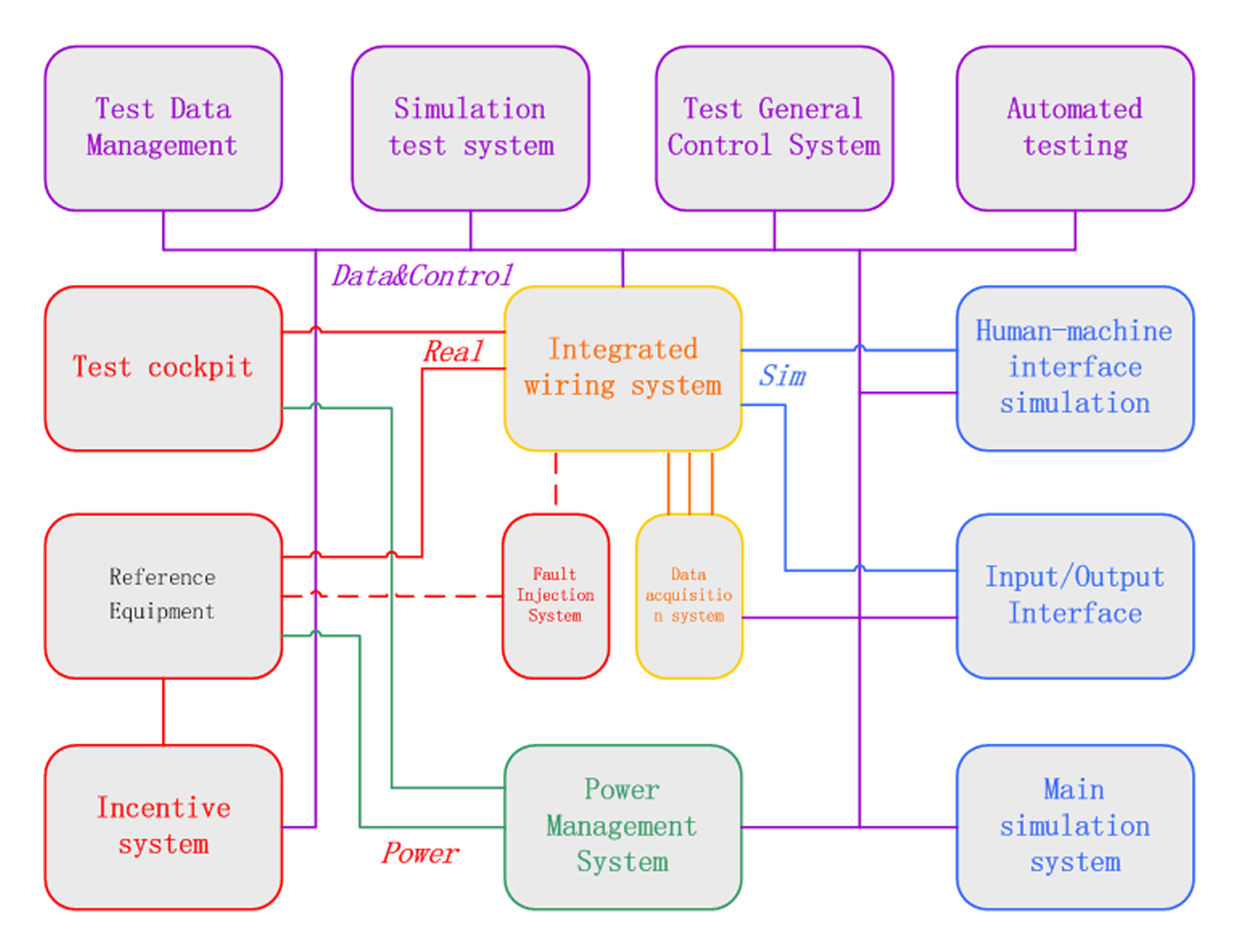

The overall architecture of the integrated electronic system test platform is shown in the following figure:

We provide customers with integrated electronic system integration and testing solutions. The main functions include:

* Provides test configuration management functions to support incremental and iterative integration of real and simulation components for problem recurrence and fault location.

* Provide program-controlled power supply and distribution management function, synchronously collect the voltage and current of the test equipment.

* It provides integrated modular simulation function, supports one-key switch between full digital simulation mode and hardware-in-the-loop simulation mode, and can directly reuse the results of system analysis and system design.

* Provide excitation-response test method, provide excitation signal for test equipment, and collect its response in real time.

* It provides dynamic comprehensive testing methods, builds real-time flight environment and battlefield environment simulation, carries out real-time parallel simulation of cross-linking equipment, provides dynamic data incentive and semi-physical simulation testing environment for the test equipment, thus completes the evaluation and verification of the product under test based on mission profile.

* Provide automated testing methods, support the expansion of test libraries and test scripts

* It provides fault injection function in physical layer, electrical layer and protocol layer, supports the configuration of fault mode and fault sequence, and realizes automatic test of fault injection.

* Provide virtual interconnection function of workshop with low delay and non-destructive real, and support cross-regional integrated joint test of avionics, flight control and electromechanical systems.

* Provide test flow and test data management platform, support the integration of test data in different formats, support the expansion and customization of data analysis algorithms.

Main Features

Integrity

* Open System Architecture to Support Design-R&D-Integration-Test-Production-Maintenance Life Cycle

* Support the simulation, integration and validation of multi-system of the whole aircraft, such as avionics, flight control, electromechanical, etc.

* It covers all Digital-Physical phases; tool chains can be linked and data chains can be inherited.

Generality

l Flexible design has the characteristics of modularization, automation, configurability and extensibility.

l It integrates many kinds of I/O, and supports users to build test configurations and test cases that satisfy different scenarios and scales independently.

Extensibility

* Distributed network architecture ensures the stability and openness of the system architecture, and is easy to expand and maintain.

* Both hardware and software adopt modular and integrated design, and the model, I/O and nodes can be incrementally expanded.

QR code

QR code QR code

QR code QR code

QR code